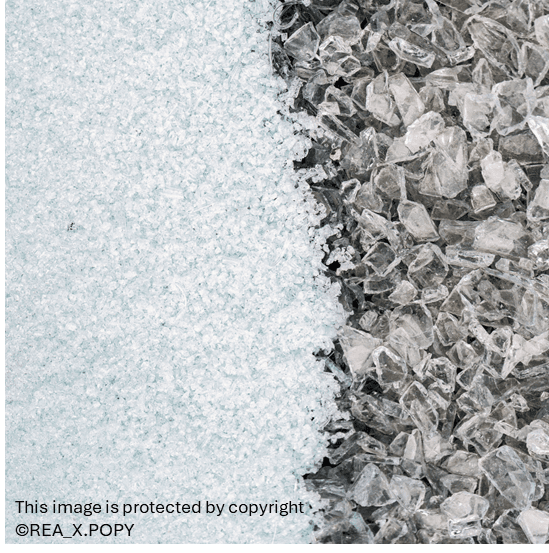

Cut embodied carbon using recycled materials

Saint-Gobain

Saint-GobainSummary

Reduced carbon by 42% through high recycled content and renewable energy in production process, with strict quality control and early project adoption.

Context

Saint-Gobain Glass faced the challenge of reducing the embodied carbon of its products to support clients in achieving lower-carbon buildings. Buildings account today for 39% of global GHG emissions: 28% from operational emissions, and the remaining 11% from materials and constructions(i). It is estimated that between 2020 and 2050, new buildings will produce around half of their emissions from embodied sources, and half from operational sources over their whole lifecycle(ii).

Saint-Gobain has also set-up ambitious CO2 emissions reduction targets (33% scope 1 and 2, 16% scope 3 in absolute value vs 2017). The production and sales of lower embodied carbon materials is a key enabler for this strategy.

Produced in: France, Spain, Germany, Italy, UK, India – available for projects worldwide

Solution

To reduce the carbon footprint of its glass production, the company prioritized sustainability across its supply chain — from raw material sourcing to manufacturing. It increased the use of recycled cullet to 64% in the final product, reducing the need for virgin raw materials and decreasing waste. Robust quality control systems were established to manage potential contamination in recycled glass, ensuring consistent product integrity.

Additionally, the company transitioned to renewable electricity for part of its manufacturing process, further cutting emissions. These initiatives were supported by close collaboration among supply chain teams, cullet managers, and a dedicated low-carbon project group, ensuring end-to-end implementation of more sustainable practices.

As a result of these measures, the company successfully established a low-carbon glass product offer, ORAÉ®, with a verified carbon footprint of just 6.64 kg CO₂ eq/m² (for 4mm glass, from cradle to grave) — representing a 42% reduction compared to standard glass, as documented in its Environmental Product Declaration (EPD).

Impact

Sustainability impact

Climate

Carbon footprint reduced by 42% in comparison to standard clear glass thanks to reduction in all scopes, mainly in:

Scope 1 and 2: Using high recycled content allows reduction in carbon emissions from the carbonated virgin raw materials together with lower energy consumption (less natural gas and electricity)

Scope 2: Electricity from renewable sources is used in the processes

Scope 3 category 1: Reduction of use of virgin raw materials allows significant reduction of emissions in this category. Some optimization of sourcing for the remaining virgin raw materials allows further reduction.

Through multiple sustainability measures implemented across supply chain — including the use of recycled materials, renewable energy, and optimized sourcing — products help address Scope 3 emissions across the value chain. By reducing the embodied carbon of glass, these initiatives contribute to lowering the overall carbon footprint of buildings during construction.

To better understand the role of glass in total life-cycle emissions, we partnered with ARUP to conduct an in-depth study on façade systems. The findings highlight the importance of both embodied and operational carbon, guiding the development of next-generation low-carbon glazing solutions. Depending on façade design and system type, glass was found to contribute between 26% and 60% of total embodied carbon, emphasizing the need for continuous innovation toward more sustainable and energy-efficient façades(iii).

Nature

Increasing the use of recycled glass (cullet) reduces the need for virgin raw materials, thereby lowering the environmental impact of extraction and preserving natural resources. The use of renewable electricity also minimizes air and water pollution associated with fossil fuel-based energy.

Social

Supports the transition to more sustainable construction practices, aligning with growing societal demand for climate-responsible buildings.

Business impact

Benefits

Beyond sustainability, responsible supply chain operations strengthen market positioning by aligning with the growing demand for low-carbon and responsibly sourced materials. These initiatives enable customers to meet green building certifications and achieve their climate goals, while reinforcing role as a trusted and forward-thinking partner in sustainable construction.

Costs

While specific cost figures are not disclosed, the initiative requires extra vigilance in sourcing recycled glass due to potential contamination risks. Managing cullet quality is critical to maintaining furnace integrity and product performance.

The rollout involved cross-functional coordination, which may increase operational complexity but is essential for success. Costs are also influenced by local availability of cullet and renewable energy.

Moving further towards more sustainable processes will require significant investments that could hamper profitability. It is crucial to anticipate and create and support interest into lower carbon materials in the construction industry.

Implementation

Typical business profile

This initiative is most relevant for construction and real estate companies aiming to meet sustainability certifications and climate targets, façade makers and specifiers working on low-carbon building envelopes, and companies seeking to decarbonize Scope 3 emissions, particularly in capital goods.

Approach

Assess the environmental footprint of existing products and supply chain operations to identify key areas for carbon reduction.

Redesign material sourcing strategies by developing a low carbon formula and transitioning to renewable energy sources for production.

Build cross-functional alignment across procurement, operations, and sustainability teams to ensure coordinated implementation and shared objectives.

Implement robust quality control systems to manage risks associated with the new formula and maintain product integrity.

Conduct pilot runs and performance testing to validate the new supply chain setup before scaling across regions or product lines.

Stakeholders involved

Company Functions: Supply chain, cullet management, operations, sustainability.

Main Providers: Internal cullet sourcing teams, renewable energy suppliers.

Other: Early adopter investors (e.g., Habitat 7, Polyclinique du Parc), façade designers, specifiers.

Key parameters to consider

Initiative maturity: Proven and commercially available; not early-stage.

Implementation timeline: It took two years to launch the first product, with careful analysis of the stakes and risks.

Average lifetime: Matches standard glass products, could be used anytime. However, it is intrinsically limited to the quantities of recycled materials. Further expansion, or even better performance shall be granted by significant investments in furnace technologies.

Technical constraints: Requires high-quality cullet, in sufficient quantities, and strict contamination control.

Geographical relevance: Applicable globally, and scalable to different facilities

Implementation and operations tips

Main challenges: Ensuring cullet purity and managing operational complexity.

Engage early with internal teams and external stakeholders.

Communicate clearly about sustainability benefits to clients. Based on third party verified EPDs.

Monitor market feedback